Nanobubbles

Nanobubbles,defined as bubbles with a diameter smaller than 1000 nanometers—particularly those under 200 nanometers—exhibit unique characteristics such as low buoyancy, high mass transfer efficiency, high reactivity, and exceptional stability. These properties make nanobubbles highly promising for applications in water treatment, industrial production, and agriculture.

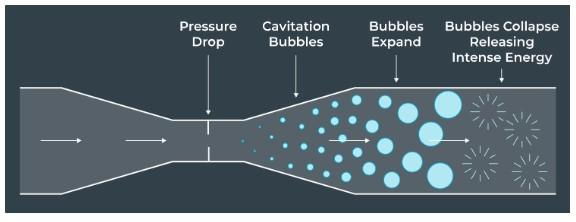

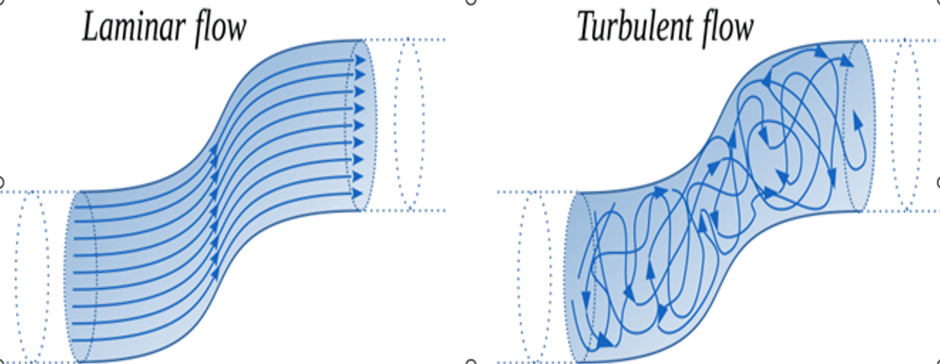

The dynamic behavior of nanobubbles is highly complex. Within extremely small spaces (micron scale) and extremely short time frames (microsecond scale), gas and liquid phases are influenced by flow field cavitation and turbulent shearing. This results in processes such as heat and mass transfer and chemical reactions between the gas and liquid phases, enabling the kinetic and potential energy of the phase interface to convert into each other.

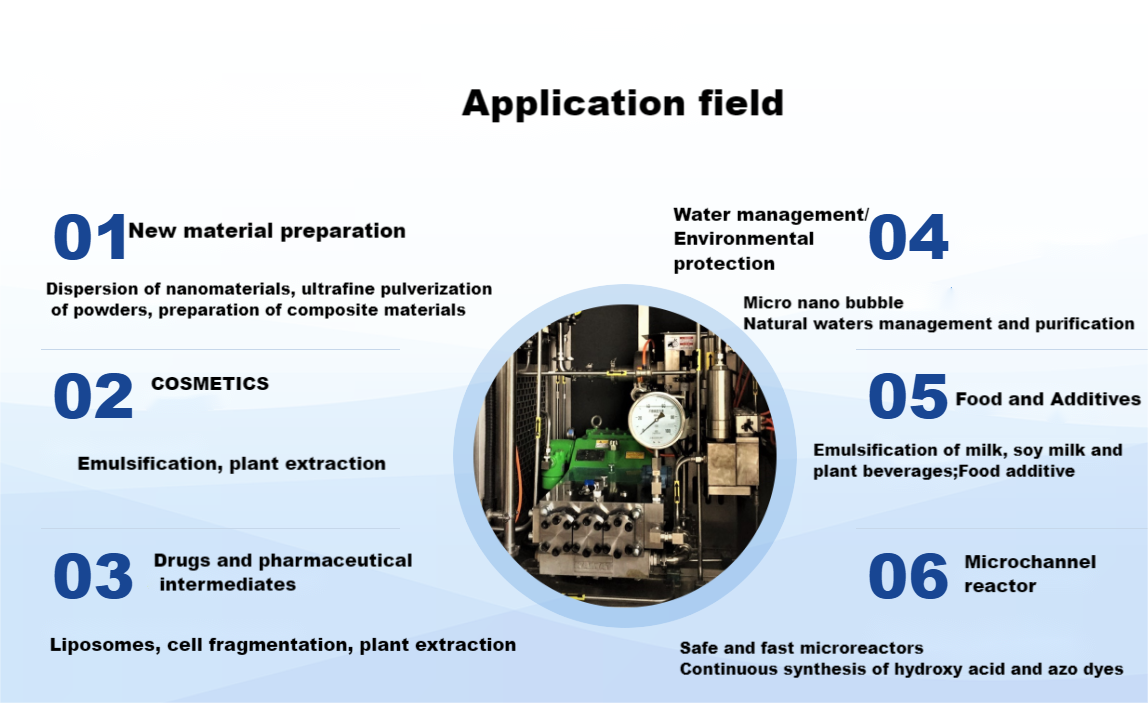

High-pressure multiphase flow technology provides an integrated solution for the preparation of nanobubbles, including multiphase mixing, crushing, dispersion, and interface restructuring. This meets the kinetic requirements of energy-limited stage intervention, allowing for the low-cost, high-throughput production of nanobubbles.

Due to their small size, nanobubbles can remain suspended in liquids (typically water) for weeks without rising to the surface and releasing gas. Although they are bubbles, they behave more like charged particles. Key characteristics of these gas nanostructures include:

Hydrophobicity:

Refers to the property of a material surface that resists being wetted by water. The hydrophobic nature of nanobubbles helps them remain stable in water and prevents them from bursting easily.

Water Repellency:

Similar in meaning to hydrophobicity, it emphasizes the repulsive force between nanobubbles and water molecules.

Charged Surface:

The surface of nanobubbles often carries an electric charge, influenced by the environment they are in. This charge affects the stability, movement behavior, and interactions of nanobubbles with other substances.

High Internal Pressure:

Due to the extremely small volume of nanobubbles, the distance between gas molecules inside them is very short, resulting in high internal pressure. This gives nanobubbles a high energy density.

Strong Surface:

Despite their small size, nanobubbles possess relatively rigid surfaces. This makes them resistant to deformation under external forces.

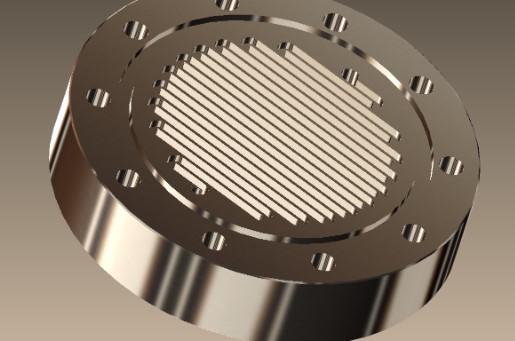

A high-pressure microchannel reactor is a type of reactor with flow channel dimensions ranging from micrometers to millimeters, manufactured using precision processing technology. It is a continuous turbulent reactor where reactants flow through tiny channels, enabling efficient heat exchange and mass transfer.

High-Pressure Microchannel Multiphase Flow Technology

A high-pressure pump pressurizes the medium, and the multiphase flow passes through a combination of microchannels that generate turbulence, laminar flow, and cavitation jet impingement at specific pressures. Under the triple influence of high-speed shear effects, high-pressure jet impingement energy, and cavitation effects caused by instantaneous pressure drop in the flow channel, the multiphase medium undergoes efficient ultra-fine crushing, π-π interactions, homogenization, and emulsification.

High-Frequency Shear + Collision + Cavitation Effects

High-Pressure Microchannel Fluid Kinetic Energy Advantage

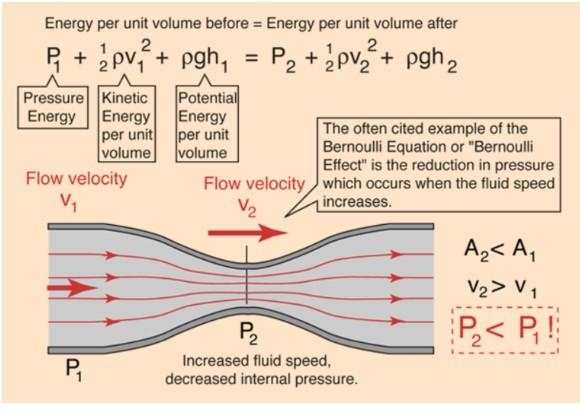

At a pressure of 200 BAR, the fluid kinetic energy density in the microchannel, calculated using Bernoulli's equation, is 100 times greater than the input fluid kinetic energy density, with a kinetic energy density value exceeding 5000 erg/cm³. As the flow channel narrows, the fluid kinetic energy density increases; when the flow channel expands, the kinetic energy is converted into cavitation energy. Continuous variation in the channel cross-section further intensifies the pulsing of kinetic energy, enhancing the mass transfer process.